Discover fresh thinking and innovative insights to help kickstart your next project.

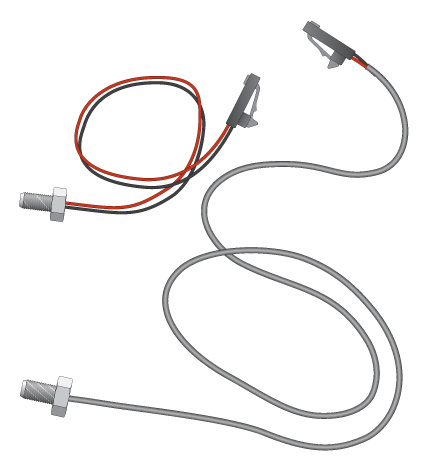

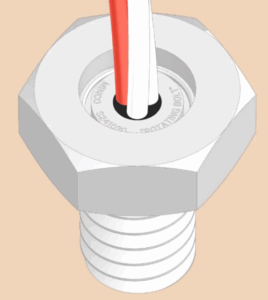

Minco’s Thermistor Bolt Sensors Excel at Medical Applications

Minco temperature sensors deliver unmatched performance, value, and reliability to meet the demanding requirements in a variety of applications. Thermistor sensors offer high sensitivity and

7 Lasting Innovations That Wouldn’t Have Been Possible Without Collaboration

In a world of broken things, engineers are fixers. But today, they’re being counted on to do more than solve problems: they’re expected to find

Should You Be Using Mica Heaters? Here’s What You Need to Know

In applications where uniform heating is a priority, mica heaters provide an efficient, cost-effective solution. They’re an excellent option for custom-designed heaters that run toward

Response Time and Temperature Sensors

An important performance characteristic of temperature sensors is response time. That is, how quickly a temperature sensor measures change in temperature.

Minco’s Globally Certified Temperature Probes

Minco temperature sensors deliver unmatched performance, value, and reliability to meet demanding requirements in a variety of industrial applications. Our advanced AS6/S6 probes offer reliable performance against bearings or in air, gas, and fluid measurement applications.

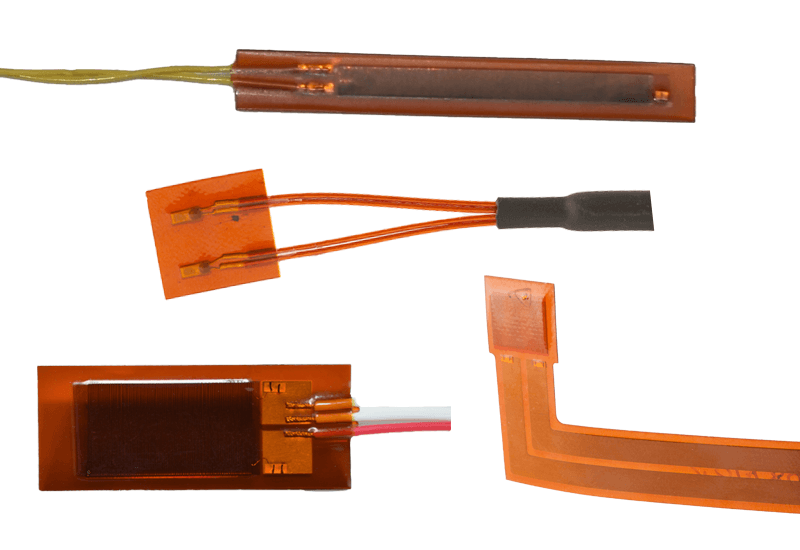

Minco’s All-Polyimide Heaters Excel at Fast Cycling Applications

All-Polyimide heaters serve as Minco’s high-performance alternative to standard polyimide heaters

Watch Minco’s New Video FAQ

Minco has been around nearly 65 years and as a result, we have encountered a fair number of FAQs – Frequently Asked Questions.

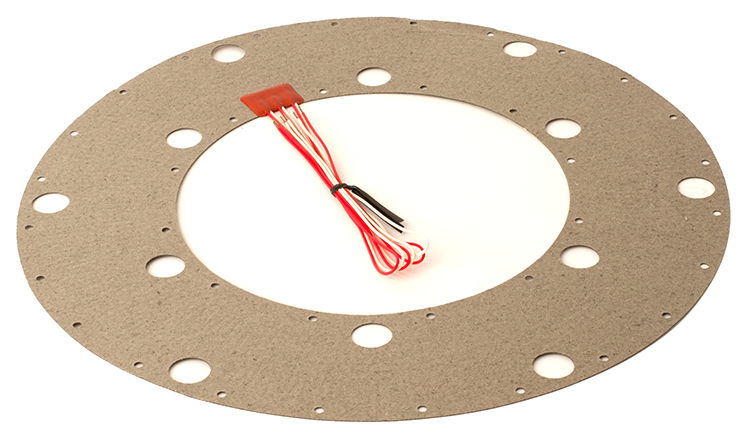

Stator Temperature Sensors with wide Hazardous Area Certifications

Minco’s S1 stator temperature sensors have broken barriers with their wide range of hazardous area certifications.

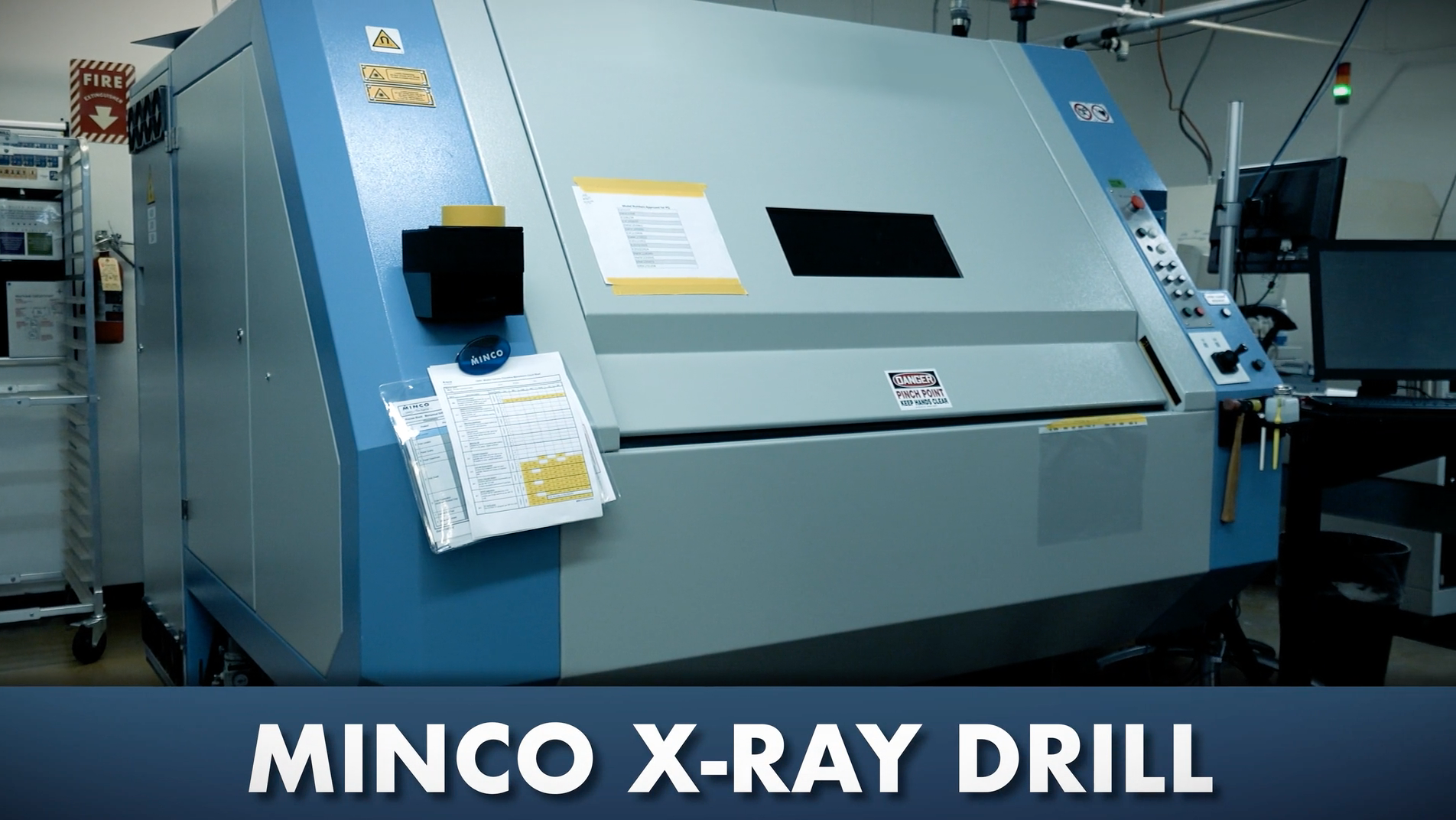

Introducing Minco’s New X-Ray Drill

Minco’s recent acquisition of a new x-ray drill improves our ability to create smaller feature sizes while demonstrating our commitment to expanding our multi-layer flex and rigid-flex capabilities.

Standard or Custom Temperature Sensors: Which are Best?

As with most difficult questions, it depends. Fortunately, Minco has you covered in either case with a wide range of sensor options including RTDs, thermocouples, thermistors, and digital IC sensors.

Search Blog Posts

Subscribe

Sign up to get Minco news.

By submitting this form, you are consenting to receive marketing emails from: Minco, 7300 Commerce Lane, Minneapolis, MN, 55432, US, http://www.minco.com. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact.

Blog Categories

Innovating Medical Devices Through Integrated Component Design

In the highly regulated medical device industry, performance, reliability, and patient safety depend on more than high-quality individual components. True innovation comes from integrating critical

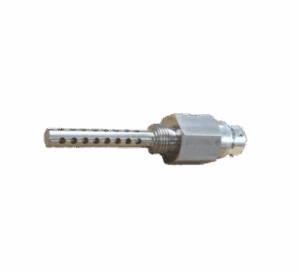

Minco’s Rotating Bolt Temperature Sensor: Precision Meets Practicality

When precision and reliability matter most, engineers turn to Minco. Our new rotating bolt temperature sensor redefines bolt-on RTD design by solving one of the

New Q&A Document: SmartHeat™ SLT Heaters for Aerospace Applications

In aerospace engineering, thermal management is always a balancing act—designing systems that maintain precise temperature control while keeping the architecture as simple, reliable, and efficient

PT100 vs PT1000 RTDs: What’s the Difference and Which Should You Choose?

When it comes to industrial temperature measurement, RTD temperature sensors (Resistance Temperature Detectors) are a go-to choice for engineers and designers seeking accuracy, stability, and

Decades of Experience, Unmatched Expertise: Minco Flexible Heaters for Space Exploration

For nearly 50 years, Minco has been at the forefront of thermal innovation, delivering solutions that define reliability and precision in space exploration. With a proven track

Minco Glass-on-Ceramic Wire-Wound RTD Elements

Minco’s Glass-on-Ceramic Wire-Wound RTD Elements offer unparalleled performance for a variety of demanding applications – now available with shorter lead times! Here’s why Glass-on-Ceramic is

New Temperature Sensors for use in Aerospace!

Aviation is one of the most demanding environments for technology. Aircraft components must perform reliably under extreme conditions, from the high, icy altitudes of flight

New Products Added to Our Popular Thermal Ribbon Product Offering!

In our ongoing commitment to advancing temperature sensing technology, Minco is proud to introduce four new Thermal Tabs to our existing product offering. These new

Non-Metallic Case Miniature Sensors

Non-metallic case miniature sensors are designed for easy installation for industrial and commercial applications. These sensors can be installed directly into drilled holes in components

RTD vs Thermocouple

Choosing the Right Temperature Sensor: RTD Sensors vs Thermocouples When it comes to temperature measurement, selecting the right sensor is crucial for accurate and reliable

Type K Thermocouple Overview

In the world of temperature measurement, accuracy is key, and one stalwart in this field is the Type K thermocouple. As industries demand reliable and

Comparative Analysis of All-Polyimide (AP), Fluorinated Ethylene Propylene (FEP), and Acrylic (WA) Flexible Heaters for Space Flight Applications

In the vast expanse of space, where extreme temperatures, vacuum conditions, and radiation are the norm, maintaining the functionality of sensitive instruments is paramount. Flexible