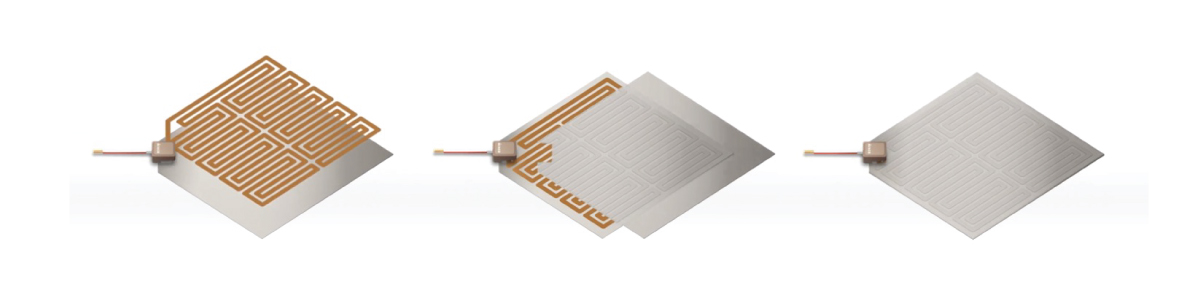

In the vast expanse of space, where extreme temperatures, vacuum conditions, and radiation are the norm, maintaining the functionality of sensitive instruments is paramount. Flexible heaters play a crucial role in ensuring the optimal performance of these instruments, making them indispensable for space flight applications. This article delves into a comparative analysis of three types of flexible heaters—All-Polyimide (AP), Fluorinated Ethylene Propylene (FEP), and Acrylic (WA)—to assist space engineers and planners in making well-informed decisions about their usage in space missions.

There are five critical performance characteristics of these different types of heaters include: material properties and structure, thermal performance, mechanical properties, radiation resistance, and environmental considerations. It is important to understand these differences when selecting a heater for space applications.

Material Properties and Structure:

All-Polyimide Heaters are known for their excellent thermal stability, All-Polyimide heaters are constructed using polyimide substrates (substrate and adhesive) and heating elements. They offer high-temperature resistance, good mechanical strength, high radiation resistance, high power density, high resistance density, and low outgassing properties. FEP heaters combine a Polyimide substrate and FEP adhesive layers with embedded heating elements. They provide good flexibility, chemical resistance, and a wide temperature operating range. Acrylic (WA) heaters utilize Polyimide substrates, Acrylic-based (WA) adhesive and heating elements. They are cost-effective, lightweight, and offer moderate radiation resistance.

Thermal Performance:

Space experiences significant temperature variations, from extreme cold to intense heat. Flexible heaters must maintain their structural integrity and performance over a wide temperature range. Materials with high thermal stability, like All-Polyimide heaters, are better suited to withstand these fluctuations without degradation or failure. FEP heaters offer a balance combination of thermal performance and flexibility, suitable for applications with moderate temperature requirements. Acrylic (WA) heaters are effective for applications with less stringent temperature demands.

Mechanical Properties:

Space missions often involve vibrations, shocks, and mechanical stresses during launch, landing, or maneuvers. Flexible heaters must be mechanically robust to endure these stresses without damage. Materials with excellent mechanical strength, such as All-Polyimide and Acrylic (WA), are vital to maintain heater integrity. FEP heaters provide flexibility, which is advantageous for conforming to curved surfaces or irregular shapes.

Radiation Resistance:

Space is filled with ionizing radiation, which can degrade materials over time. Flexible heaters should have resistance to radiation to maintain their performance and longevity. Materials like All-Polyimide and Acrylic (WA) are known for their radiation resistance, making them suitable for long-duration space missions. FEP heaters exhibit moderate radiation resistance, suitable for missions with moderate radiation levels.

Environmental Considerations:

In the vacuum of space, outgassing can be problematic. Materials that release gases or particles when exposed to vacuum conditions can contaminate nearby equipment or optics. All-Polyimide and Acrylic (WA) are both low outgassing materials, making them suitable for environments with vacuum conditions. FEP heaters’ excellent chemical resistance and low outgassing makes them preferable for applications where exposure to harsh chemicals is a concern.

Selecting the right flexible heater for space flight applications depends on specific mission requirements. A more comprehensive list of vital characteristics can be found in the table below. From material composition and environmental suitability to thermal stability, temperature resistance, and mechanical properties, this table offers a valuable reference point for engineers, space agencies, and researchers seeking to make informed decisions about the most suitable flexible heater for their specific space mission requirements. Each heater type’s strengths and limitations have been examined to guide the selection process, ensuring that the chosen technology aligns seamlessly with mission objectives and environmental conditions.

|

Property |

All-Polyimide |

FEP |

Acrylic (WA) |

|

Material Properties |

Polyimide Substrate and Adhesive, |

Polyimide Substrates, FEP Adhesive Layers, |

Polyimide Substrate, |

|

Environmental |

Low outgassing |

Low outgassing, Chemical resistance |

Low outgassing resistance |

|

Thermal Stability |

Excellent |

Balanced |

Moderate |

|

Temperature Resistance |

High |

Broad Range |

Less Stringent |

|

Temperature rating |

-200°C to +260°C |

-200°C to +200°C |

-200°C to +150°C |

|

Mechanical Strength |

Excellent |

Flexible |

Excellent |

|

Flexibility |

Flexible |

Flexible |

Flexible |

|

Radiation Resistance |

High |

Moderate |

Moderate |

|

Power Density (W/in² @ 25°C) |

90 |

40 |

30 |

|

Resistance Density, Maximum (Ω/in²) |

1500 |

450 |

1500 |

|

NASA Compliance |

S-311-P-841 |

S-311-P-079 |

EEE-INST-002, |

|

Longevity and reliability |

Known for reliability and long service life |

Known for reliability and durability |

Reliable for missions with moderate environmental demands |

Choosing the appropriate flexible heater for space missions is a critical decision. All-Polyimide heaters are best suited for high-temperature and radiation-prone environments, ensuring reliability and longevity. FEP heaters strike a balance between thermal performance and flexibility, making them versatile for moderate temperature applications. Acrylic (WA) heaters, with their cost-effectiveness and moderate radiation resistance, cater to missions with less demanding environmental conditions.

This comprehensive comparative analysis equips space mission planners and engineers with valuable insights. By understanding the strengths and limitations of All-Polyimide, FEP, and Acrylic (WA) flexible heaters, informed decisions can be made, contributing significantly to the success of future space endeavors.