TEMPERATURE

SENSORS

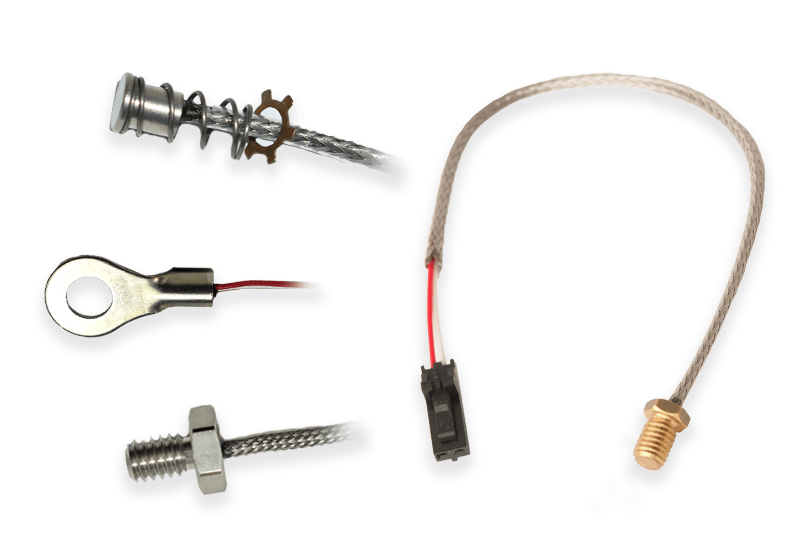

Miniature Sensors

Minco’s miniature temperature sensors were originally designed as embedment sensors in bearing shoes to protect rotating machinery from potentially catastrophic overheating events. While this application remains a mainstay, the use of these sensors has expanded into medical diagnostic, semicon, aerospace, oil and gas, food and beverage, and industrial equipment. These small-profile sensors save space and weight while providing fast thermal response time and designs suitable for high levels of vibration. Minco miniature sensors are available in single or dual element RTDs and thermocouples — as well as in a multitude of standard and custom case designs to fit your unique needs. Special features include: spring-loading, connectors and hazardous area certifications to further enhance the value of these sensors.

MINCO OFFERS A VARIETY OF MINIATURE SENSORS:

- Bearing embedment sensors

- Bolt-on sensors

- Economy sensors

- Hazardous area sensors

Need help building the right part?

Get technical information around our sensor offerings — or build a part number according to your specifications through our product guide.

Looking for a customized sensing solution?

Half of the sensors we produce are custom-engineered designs developed for challenging applications. Our Engineers are ready to help.

Interested in a standard part?

We’re here to help you find exactly what you need.

ALL TEMPERATURE SENSOR SOLUTIONS

Miniature Sensors

Miniature Sensors

EXPLOREProbe & Probe Assemblies

Probe & Probe Assemblies

EXPLOREStator Sensors

Stator Sensors

EXPLORESurface Sensors

Surface Sensors

EXPLOREHVAC/Building Automation Sensors

HVAC/Building Automation Sensors

EXPLOREElements

Elements

EXPLOREHumidity Sensors

Humidity Sensors

EXPLORELevel Sensors

Level Sensors

EXPLORETEMPERATURE SENSOR RESOURCES

- Minco Temperature Sensor and Instrument Product Guide - Learn More

- Choosing the Right Temperature Sensor: RTD Sensor vs Thermocouple - Learn More

- HVAC Product Guide - Learn More

- Temperature Sensor Application Matrix: Not sure which Minco products fit your application? Read the Application Guide

- Minco Time Constant Considerations Sensors White Paper - Learn More

- Minco Blog - Monitor Temperature in Ultra Low Freezer Applications - Learn More

- Type K Thermocouple Overview - Learn More