Surface temperature Sensors

MINCO OFFERS SURFACE SENSORS WITH A

VARIETY OF ATTRIBUTES:

- Design Type

- Element Type

- Performance Specifications

- Applications

- Installation Methods

- Choose an option below to learn more...

Minco Thermal Ribbon Product Offering

Thermal Tab™ and Thermal Ribbon™ Sensors

Install these compact sensors anywhere for accurate point sensing and fast response. All Thermal-Tab modules use a thin-film RTD element. All Thermal-Ribbon models conform to EN60751 Class B tolerance when ordered with a PD platinum element.

- First response surface sensing in aerospace, medical and industrial devices

- Rugged lamination construction

- Polyimide, silicone rubber or Mylar™ insulation

- All models are RoHS compliant

Thermal-Tab Specifications

Dimensions W x L x Tmax | Element options | Insulation | Temperature range | Lead wires | Time constant* | Features | Model |

0.20 x 0.50 x 0.08″ (5 x 12 x 2 mm) |

| Polyimide with elastomer cover coat | -50 to 155°C -58 to 311°F | AWG 26, PTFE insulated | 0.8 sec. | Stocked for immediate shipment |

|

0.20 x 0.60 x 0.08″ (5 x 15 x 2 mm)

|

| Polyimide | -50 to 200°C -58 to 392°F | AWG 26, PTFE or polyimide insulated | 1.0 sec. | Platinum models in stock |

|

0.20 x 0.60 x 0.08″ (5 x 15 x 2 mm) |

| Polyimide film | -50 to 260°C -58 to 500°F | AWG 26, PTFE or polyimide insulated | 0.4 sec. | Highest temperature capability | S100820 |

0.20 x 0.60 x 0.12″ (5 x 15 x 3 mm) |

| Silicone rubber with elastomer cover and foil backing | -50 to 155°C -58 to 311°F | AWG 24, Silicone insulated | 1.3 sec. | Waterproof; suitable for continuous immersion | S667 |

0.20 x 0.60 x 0.045″ (5 x 15 x 1.15 mm) |

| Polyimide film | -50 to 200°C -58 to 392°F | AWG 26, PTFE or polyimide insulated | 0.6 sec. | Thinnest profile | S100725 |

0.30 x 0.60 x 0.10″ (7 x 15 x 2.5 mm) |

| Polyimide film | -50 to 200°C -58 to 392°F | AWG 22, PTFE or polyimide insulated | 1.2 sec. | Heavier leadwire for applications requiring ruggedized design | S100724 |

0.40 x 0.80 x 0.08″ (10 x 20 x 2 mm) |

| Polyimide film | -50 to 200°C -58 to 392°F | AWG 26, PTFE or polyimide insulated | 0.9 sec. | Larger surface area for easier handling and maximum adhesive bond | S100723 |

0.40 x 0.80 x 0.08″ (10 x 20 x 2 mm) |

| Silicone rubber | -50 to 220°C -58 to 428°F | AWG 26, PTFE or polyimide insulated | 1.5 sec. | High temperature rating, available with wide range of element options | S100721 |

Thermal-Ribbon Specifications

Dimensions W x L x Tmax | Element options | Insulation | Temperature range | Lead wires | Time constant* | Features | Model |

0.20 x 1.50 x 0.030″ (5.1 x 38.1 x 0.8 mm) |

| Polyimide | -200 to 200°C -328 to 392°F | AWG 34, PTFE insulated | 0.15 sec. | Wire-wound nickel-iron for high resistance in small package |

|

0.30 x 0.30 x 0.025″ (7.6 x 7.6 x 0.7 mm) |

PE | Polyimide with foil backing | -200 to 200°C -328 to 392°F | AWG 28, PTFE insulated | 0.15 sec. | Wire-wound element |

|

0.75 x 0.75 x 0.04″ (19 x 19 x 1.0 mm |

| Mylar | -200 to 150°C -328 to 302°F | AWG 30, PTFE insulated | 0.3 sec. | Wire-wound nickel-iron flat element for high resistance |

|

Notes: Tmax is measured over the lead bulge.*Time constant is in water at 1 m/sec.

Leadwire insulation codes |

|

S25, S38, S651, S665, | Leave |

S17624, S100721, S100723, | |

Sensing Elements

Sensing element specifications** | Code | |

Platinum (0.00385 TCR) (EN60751, Class B) | 100 ±0.12% at 0°C | PD |

Platinum (0.00385 TCR) | 100 ±0.22% at 0°C | PE |

Platinum (0.00385 TCR) | 1000 ±0.12% at 0°C | PF |

Platinum (0.00375 TCR) | 1000 ±0.12% at 0°C | PW |

Platinum (0.00385 TCR) | 10,000 ±0.12% at 0°C | PS |

Nickel-iron (0.00518 TCR) | 604 ±0.26% at 0°C | FA |

Nickel (0.00618 TCR) (DIN43760 NI100, Class | 100 ±0.22% at 0°C B) | NB

|

Model S667 is waterproof and suitable for continuous immersion. Use it to monitor the temperature of water in a tank or container, or on equipment that must withstand wash-down or immersion.

Check with Minco for suitability in other liquids.

|

Specification and order options

S17624 | Model number from table |

PD | Sensing element from table |

Z | Number of leads:

|

T | Lead wire insulation code from table at left |

12 | Lead length in inches: S665/S667: 60″ max.

|

A | Adhesive backing:

|

Stop here for all models except S665 or S667.For models S665 and S667, add: | |

C | Compliancy: C = RoHS Compliance |

S665PDZT12AC = Sample part number | |

Notes: PSA reduces temperature range to -20 to 177°C (-4 to 350°F) and adds 0.005″ (0.1 mm) to thickness.

Minco can custom-wind Thermal-Ribbon elements in virtually any shape and size. We can profile sensing elements to provide increased sensitivity in selected zones, and provide packaging to perfectly fit your applications. Contact Minco Sales and Customer Service today to discuss your application. |

Discoil™ Thermal Ribbons

Install these compact sensors anywhere for accurate point sensing. Discoil RTD elements are wound on a single plane for faster time response.

Discoil Thermal Ribbon Specifications

Dimensions | Element | Insulation | Temperature | Lead wires | Time | Features | Model |

W x L x Tmax | options |

| range |

| constant* |

|

|

0.79 x 1.87 x 0.055″ (20 x 47.5 x 1.4 mm) solder pad version shown

|

PE | Polyimide (clear polyester available) | -73 to 200°C -100 to 392°F | (Optional) AWG 24, PTFE insulated | 0.10 sec. | Only 0.010″ thick over element, fast time response, platinum PD accuracy available |

|

1.00 x 1.25 x 0.090″ (25.4 x 31.8 x 2.3 mm) |

| Silicone rubber with polyimide backing | -62 to 220°C -80 to 428°F | AWG 24, silicone rubber insulated | 0.2 sec. | High temperature rating, platinum PD accuracy available |

|

PE22 |

|

Notes: Tmax is measured over the lead bulge. *Time constant is in water at 1 m/sec.

Sensing Elements

Sensing element specifications** | Code | |

Platinum (0.00391 TCR) | 100 ±0.5% at 0°C | PA |

Platinum (0.00391 TCR) | 100 ±0.11% at 0°C | PB11 |

Platinum (0.00391 TCR) | 100 ±0.22% at 0°C | PB22 |

Platinum (0.00385 TCR) (EN60751, Class B) | 100 ±0.12% at 0°C | PD, PD12 |

Platinum (0.00385 TCR) | 100 ±0.36% at 0°C | PE (Discoil) |

Platinum (0.00385 TCR) | 100 ±0.5% at 0°C | PE (Strip sensing) |

Platinum (0.00385 TCR) | 100 ±0.22% at 0°C | PE22 |

Nickel-iron (0.00518 TCR) | 604 ±0.26% at 0°C | FA |

Copper 427 | 10 ±0.20% at 25°C | CA |

Nickel 672 | 120 ±0.3% at 0°C | NA |

Specification and order options

S32 | Model number from table | |

PB22 | Sensing element from table | |

Z | Number of leads:

X = 4 leads

| |

36 | Lead length in inches

(Specify 0 for solder pads, option on S17422 only) | |

A | Adhesive backing:

| |

S32PB22Z36A = Sample part number | ||

Notes: PSA reduces temperature range to -20 to 177°C

Strip Sensing Thermal Ribbons™

These models average temperatures along their length to eliminate point measurement errors. Wrap them around cylinders or adhere them to flat surfaces.

Strip Sensing Thermal Ribbon Specifications

Dimensions W x L x Tmax | Element options | Insulation | Temperature range | Lead wires | Time constant* | Features | Model |

0.50 x 1.25 x 0.050″ (12.7 x 31.8 x 1.3 mm) |

| Polyimide | -73 to 200°C -100 to 392°F | AWG 26, PTFE insulated | 0.17 sec. | Easy motor installations |

|

0.375 x 4.00 x 0.075″ (9.5 x 101.6 x 1.9 mm) |

| Silicone rubber w/ polyimide backing | -62 to 220°C -80 to 428°F | 0.6 sec. | Platinum PD accuracy |

| |

|

| ||||||

0.375 x 4.00 x 0.065″ (9.5 x 101.6 x 1.7 mm) |

| Polyimide | -200 to 200°C -328 to 392°F | 0.2 sec. | Wire-wound nickel-iron for high resistance, thin element |

|

Model S3238: Model S3238 is specially designed to sense stator temperatures in motors and generators. An alternative to the “stick” sensors, the S3238 mounts on the end of turns of stator windings and provides an easy way to add overtemperature protection.

S3238 specification and order options

S3238 | Model number S3238 |

PA | Sensing element from table |

Y | Number of leads:

|

T | Lead insulation:

|

36 | Lead length in inches: :

|

U | Lead configuration:

|

A | Adhesive backing:

|

S3238PAYT36UA = Sample part number | |

Specification and order options

S34 | Model number from table (except S3238) |

PB22 | Sensing element from table |

Y | Number of leads: Y = 2 leads Z = 3 leads (required on CA) X = 4 leads (PD only) |

36 | Lead length in inches: 36” stocked |

A | Adhesive backing: A = No adhesive B = Pressure-sensitive adhesive (PSA) |

S34PB22Y36A = Sample part number | |

Notes: PSA reduces temperature range to -20 to 177°C (-4 to 350°F) and adds 0.005″ (0.1 mm) to thickness.

Thermistor Thermal-Tab™

Model TS665 and TS667 offer extremely sensitive NTC thermistors for applications with small temperature changes. Model TS667 also features waterproof construction, making it suitable for continuous immersion.

Thermistor Thermal-Tab Specifications

Dimensions W x L x Tmax | Element | Insulation | Temperature | Lead wires | Time | Features | Model |

0.20 x 0.47 x | TF, TK | Polyimide with | -50 to | AWG 26, PTFE insulated | 0.8 sec. | Small, |

|

0.20 x 0.60 x | Silicone | AWG Silicone | 1.3 sec. | Waterproof, |

|

Specification and order options

TS665 | Model number from table |

TF | Sensing element from table |

Y | Number |

40 | Lead max.) |

A | Adhesive backing:

|

C | Compliancy: C = RoHS compliant |

TS665TFY40AC = Sample part number | |

Note: PSA reduces temp. range to -20 to 177°C (-4 to 350°F) and adds 0.005″ (0.1 mm) to thickness.

Sensing Elements

|

Sensing |

Code |

|

NTC thermistor 50k ±1% at 25°C |

|

|

NTC thermistor 10k ±1% at 25°C |

|

Thermistor Thermal-Ribbon™

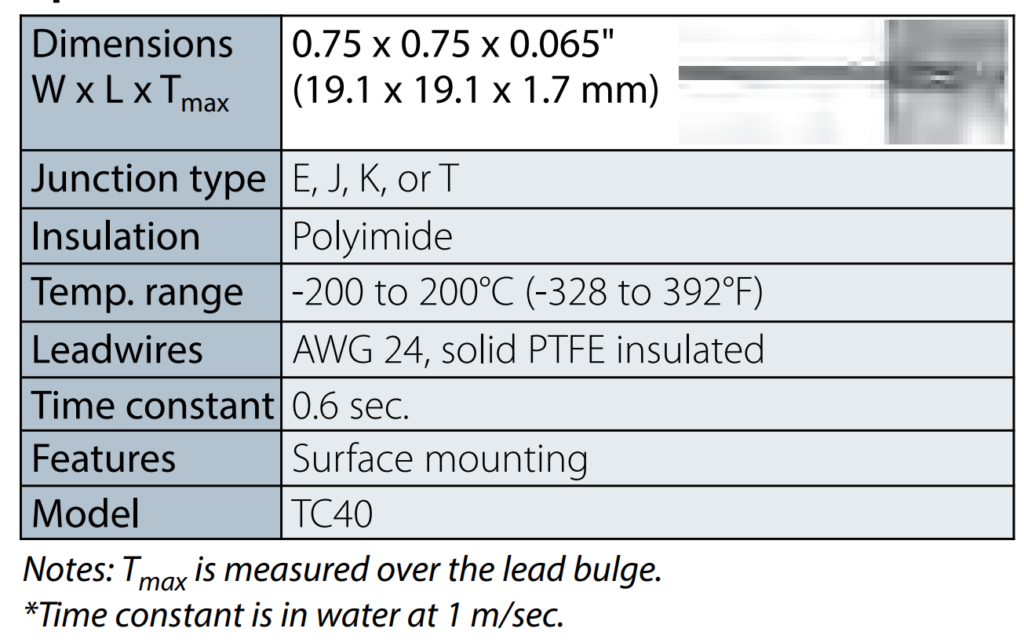

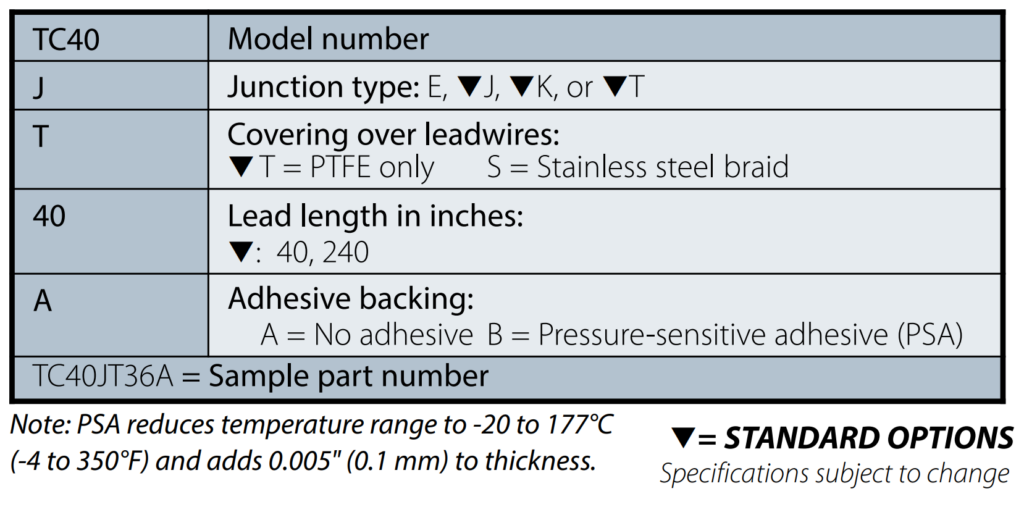

TC40 is a patch-style thermocouple that adheres to all types of surfaces for quick and easy mounting.

Specifications

Specifications and order options

Need help building the right part?

Get technical information around our sensor offerings — or build a part number according to your specifications through our product guide.

Looking for a customized sensing solution?

Half of the sensors we produce are custom-engineered designs developed for challenging applications. Our Engineers are ready to help.

Interested in a standard part?

We’re here to help you find exactly what you need.