By Darrell Hyde

Reliable cold storage of vaccines, tissue and plasma samples is regularly required in a variety of medical and pharmaceutical applications. Temperature measurement in applications as low as -120°F presents challenges on multiple fronts. With Minco’s extensive experience using our wire-wound platinum RTD (resistance temperature detector) technology, paired with 4-20mA transmitters for simple and reliable signal transmittal, the following challenges of low temperature measurement can be overcome.

Many temperature sensors simply are not rated for temperatures below -50°F. This is especially true of thin-film RTDs which lose accuracy and reliability at low temperatures due to thermal expansion issues – or in this case thermal contraction issues – where the rigidly bonded thin-film materials (ceramic, platinum, glass, lead wires) contract at different rates, causing strains on the sensing element. At best, these strains produce errors in the sensor output. At worst, the strains can cause cracks or breaks, leading to element failure of the sensing element. Our wire-wound RTDs are constructed to avoid this strain issue which makes them suitable at much lower temperatures – in some cases, as low as -452°F.

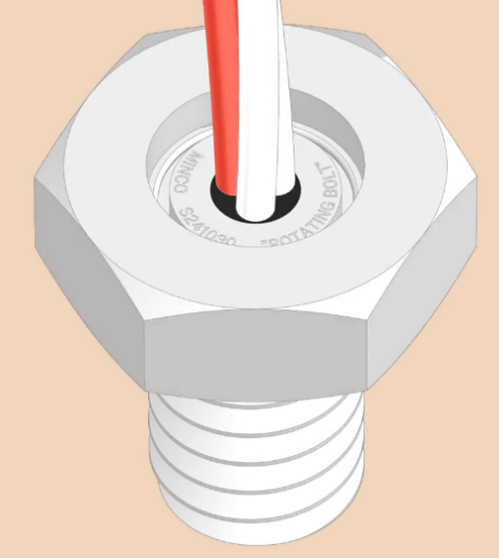

Not surprisingly, temperature sensors indicate their temperature, not the temperature of the contents of a freezer or refrigerator. This is fine if you never open the freezer door but that is not very practical! When you do open the door, warmer air enters the freezer and will likely cause the sensor to indicate a temperature that is warmer than the actual freezer contents — which have a larger mass than the warmer air that just entered. Our Thermal-Vial assemblies solve this problem by enclosing the temperature sensor in a vial containing a liquid with a low freezing point. Being in the vial will slow down the rate of change of the temperature sensor to more accurately match that of the contents. After all, you want to know the temperature of the contents – not the air in the freezer. Moreover, you definitely don’t want to have a false alarm triggered by the temperature sensor measuring a short blast of warm air instead of the freezer’s contents.

A third challenge is getting the sensor signal to the control system or recording device. This can be done wirelessly but that introduces risks of transmitter failure as well as signal loss. Minco utilizes a 4-20mA transmitter wired directly to the sensor and located on the outside of the freezer or refrigerator. The 4-20mA signal is sent by a simple two-wire configuration to the control system. This current (mA) signal is immune to long wire runs, which could adversely affect accuracy of the sensor through added circuit resistance or electrical noise. An optional local display is available if a visual indication of temperature is desired at the freezer itself.

See Minco Thermal Vial for additional information.

An alternative design capable of even lower temperature measurement – as low as -452°F is our Refrigeration and Freezer Temperature Sensor which utilizes the same wire wound RTD and 4-20mA transmitter. See Minco Refrigeration and Freezer Temperature System for more information.

Contact your Minco Sales team for assistance with these standard products, a custom configuration or any temperature sensing need.