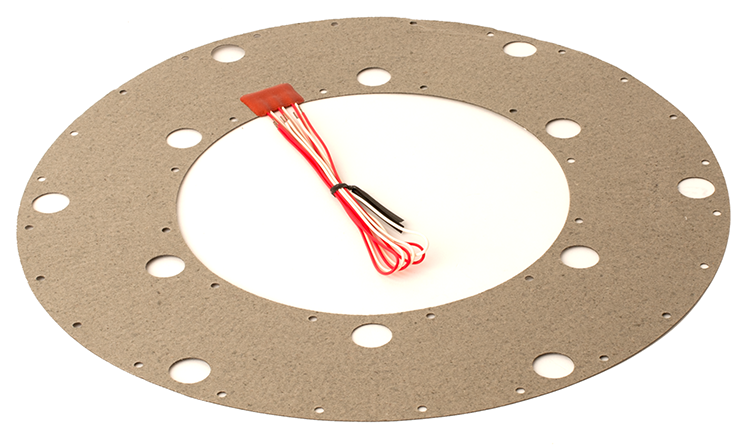

Mica THERMOFOILTM Heaters

In applications where fast warmup and high operating temperatures are necessary, mica heaters deliver flexible wattage capacity capable of providing uniform heating across a variety of shapes and sizes.

WHAT ARE MICA THERMOFOILTM HEATERS

Mica Thermofoil heaters consist of an etched foil element sandwiched between layers of mica. Installed by clamping to heat sinks, mica heaters provide the ultimate temperature and wattage capability for fast warmup.

MICA THERMOFOILTM HEATER applications

- Semiconductor processing

- Packaging, strapping, and sealing equipment

- DNA thermocycling

- Food service applications

- Plastic and rubber molding supplemental heat

MICA THERMOFOILTM HEATER Features

- High watt density (up to 110 W/in²) delivers faster processing times than conventional mica heaters

- Custom profiling and mechanical clamping capabilities produce uniform temperature

- UL certification is available which can save time and money for end-use UL device recognition

- Can be factory formed to curves

- Broad temperature range: -150°C to 600°C (-238°F to 1112°F) provides faster processing and cycle times for greater production output

MICA THERMOFOILTM HEATER APPLICATIONS

- Extrusion Equipment: employed in extruders to maintain the temperature of the extrusion barrels, enabling the processing of various materials like plastics, rubber, and food products.

- Packaging Machinery: used in packaging equipment for tasks such as heat sealing, bag making, and shrink wrapping, ensuring proper sealing and packaging of products.

- Ovens and Dryers: utilized in industrial ovens and dryers for applications like baking, curing, drying, and heat treating in industries ranging from food processing to manufacturing.

- Mold and Platen Heating: used to heat molds and platens in plastic and rubber processing machinery, ensuring proper molding and shaping of materials.

- Medical Devices: used in medical equipment such as blood analyzers, sterilization devices, and diagnostic equipment, where precise and consistent heating is essential.

- Semiconductor Processing: applications in semiconductor manufacturing equipment for processes like wafer processing, bonding, and annealing, ensuring controlled and uniform heating.

- Laboratory Instruments: used in laboratory equipment such as incubators, ovens, and analytical devices, providing precise and stable heating conditions for experiments and research.

- Aerospace and Automotive: employed in aerospace and automotive applications for tasks like composite curing, de-icing systems, and engine preheating, ensuring reliability and safety in critical components.

- Food Processing: applications in food processing equipment for tasks such as extrusion, baking, and drying, ensuring food safety and quality.

- Industrial Equipment: used in various industrial applications, including heat staking, welding, and adhesive bonding, where localized or uniform heating is required for assembly processes.

Want to learn more about the simplicity, stability and safety a customized Mica Heater solution can deliver to your next project? Read the product brochure.