FLEX

CIRCUITS

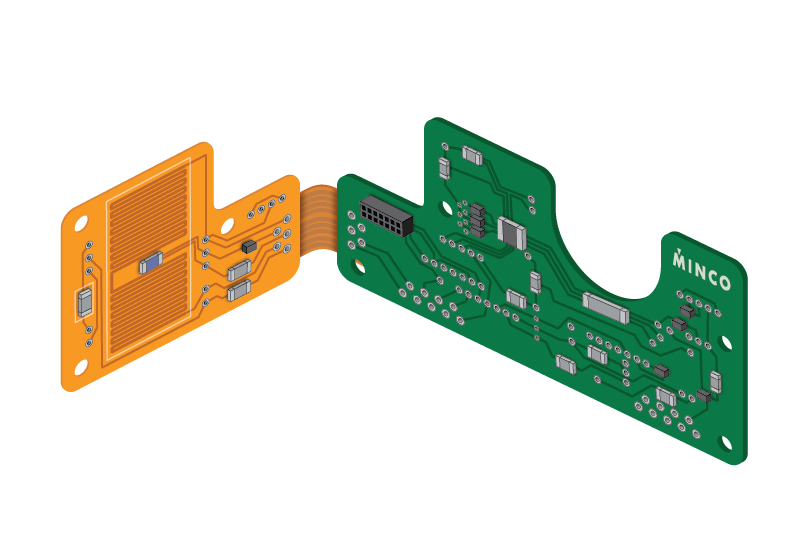

RIGID FLEX PCB

You’re looking to remove as much weight and cost as possible from your designs — while improving performance in the field. You probably love that challenge. So do we. That’s why Minco invests heavily in rigid flex circuit technologies — and has gone through rigorous testing to ensure the highest possible reliability and repeatability in our processes.

Minco Products has firmly established itself as a leading and reliable manufacturer of flexible printed circuit boards (Flex PCB). With a commitment to excellence and a focus on quality, Minco Products has consistently delivers innovative and precision-engineered Flex PCB solutions to meet the diverse needs of its clients. Our dedication to maintaining the highest standards in manufacturing is reflected in the durability, reliability, and performance of our flexible circuit boards. Whether it’s for medical devices, aerospace applications, or industrial electronics, Minco Products stands out as a trusted partner, providing top-notch rigid flex PCB solutions that exemplify durability, flexibility, and unparalleled quality in the ever-evolving field of electronics manufacturing.

- Minco Flex Circuit Technology Overview - Learn More

- Designing for Flexibility and Reliability - Learn More

- Guide to Integrated Flex Circuits - Learn More

- Common Specification Pitfalls To Avoid - Learn More

- Project Case Study: Defense Missile Delivery System Control Unit. Read the Case Study

- Project Case Study: Medical Catheter Wound Cauterizing. Read the Case Study

- Replacing a Wire Harness with a Flex Circuit - Learn More

- The Answer Isn't Always Rigid Flex PCB - Learn More

- Advantages of Pads Only Panel Plating Techniques - Learn More

Design Smarter Circuits with Minco

What do you need to submit a flex PCB project to Minco?

- Notes: Required specifications, materials, testing, clarification of views, electrical requirements, plating and final finish, and assembly details.

- Circuit views: At least one view that shows overall size, required dimensions, tolerance needs, established datums, and assembly needs.

- Stackup: For complex circuits with multiple layers, isolated cutaways/exposures, and multiple stiffeners, a stackup view of materials helps clarify requirements.

- Bill of Materials (BOM): If the circuit includes items such as components and connectors, a BOM should include these details.

- Schematic: The schematic should highlight any specific electrical needs and component callouts for the footprints.

Design Smarter Circuits with Minco

What do you need to submit a flex project to Minco?

Identify the Right Configuration

Consider Integrated Components

Select Application-Ready Specs

Test for Physical and Electrical Performance

ALL FLEXIBLE CIRCUIT SOLUTIONS

RIGID

FLEX

PCB

RIGID

FLEX

PCB

EXPLORE

HIGH DENSITY

INTERCONNECT

HIGH DENSITY

INTERCONNECT

EXPLORE

CIRCUIT

ASSEMBLIES

CIRCUIT

ASSEMBLIES

EXPLORE

MINIATURE

FLEX-COILS

MINIATURE

FLEX-COILS

EXPLORE

SINGLE & DOUBLE

LAYER FLEX

SINGLE & DOUBLE

LAYER FLEX

EXPLORE

MULTI-LAYER FLEX

MULTI-LAYER FLEX

EXPLORECUSTOM FUNCTIONALITY

CUSTOM FUNCTIONALITY

EXPLOREOUR TECHNOLOGY ROAD MAP

OUR TECHNOLOGY ROAD MAP

EXPLOREENGINEERED SOLUTIONS

OVERCOME ANY DESIGN CHALLENGE

WHY CHOOSE MINCO?

PROVEN EXPERTISE

For more than 60 years, Minco has helped engineering teams design and build the mission critical devices that power high reliability industries. We know what it takes to get the job done — on time and on budget.

INTEGRATION ACROSS PRODUCT LINES

No matter the challenge, Minco engineers bring best practices from hundreds of similar engagements worldwide to help our customers plan, design and integrate the best solutions for their programs.

MINCO CERTIFICATIONS

• ISO9001:2008

• ISO 9001:2015

• AS9100C certified

• AS9100D certified

• NADCAP accredited

• ITAR registered

• IPC-6013 Class III Product

• IPC J-STD Certified

• IPC CID Certified CAD

LET'S TALK E2E

Ready to take the next step and explore powerful design innovation? Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance.