By John Baichtal

In our business, strong communications among engineers makes for better products and happy customers. This truism was demonstrated in a recent project we helped build for a defense-industry manufacturer: the control unit of a newly modified missile delivery system.

makes for better products and happy customers. This truism was demonstrated in a recent project we helped build for a defense-industry manufacturer: the control unit of a newly modified missile delivery system.

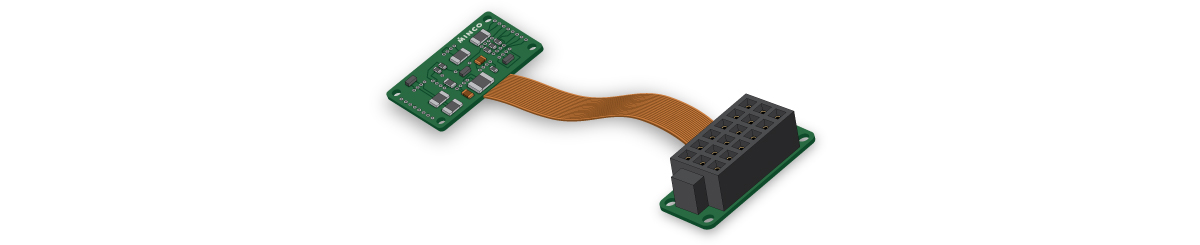

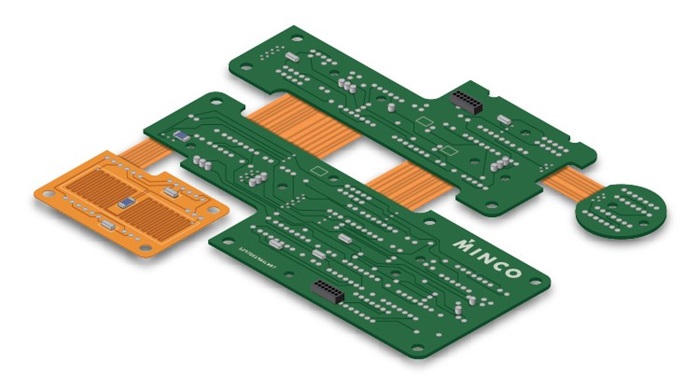

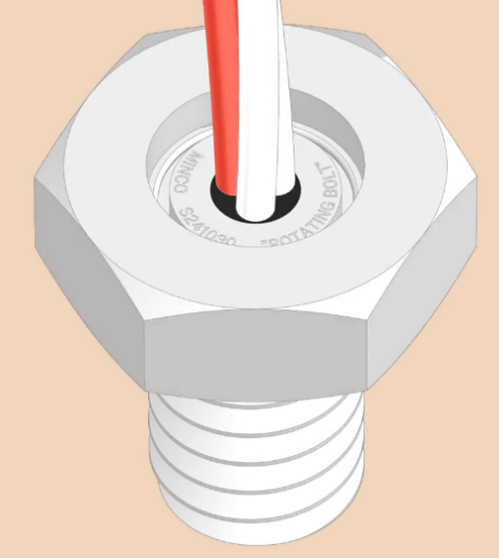

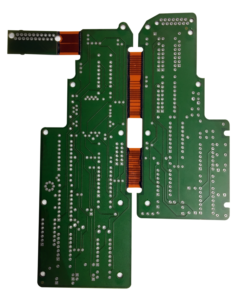

Like many defense-related contracts, the control unit project came with a very robust set of certifications and specifications. Despite these challenges, our engineer-to-engineer (E2E) relationship with the customer as well as our excellent technological capabilities helped ensure a successful conclusion.We designed and manufactured a 6-layer rigid flex circuit with an extensive subassembly, able to connect a variety of components throughout the control unit. Minco’s Rigid Flex assemblies consist of both flexible high density interconnects as well as rigid printed-circuit boards (PCBs), the latter able to accommodate both through-hole and surface-mount components as small as 0201. This project also featured copper shields secured with a pressure-set adhesive. By replacing the wiring harness with a flex circuit, significant weight and size reductions became possible. The redesigned control unit is 70% smaller, 40% lighter, and features a 50% increase in battery life.

It turns out most projects can benefit from flex technology. Such circuits are thinner and lighter than conventional wiring bundles, allowing you to power components throughout the enclosure. Not only are flex circuits more compact, they’re also tougher. The materials used are robust enough to withstand high vibration, resist abrasion, and endure thousands to millions of flexing cycles. Flex circuits’ polyimide construction makes them ideal for rigorous markets such as aerospace, defense, and medical.

Visit Minco.com to learn more about our flex technology or to discover how you can partner with our engineers in your next project.