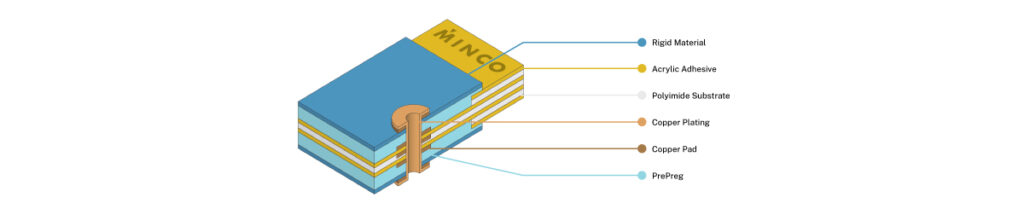

Rigid flex printed circuit boards (PCBs) typically cost 7x as much as a tradition PCBs and 2-3x more than flex PCBs. Why is this? Simply put, rigid flex PCBs require a far more complex construction with many layers, more material use and numerous assembly steps.

Rigid flex PCBs aren’t just for military, aerospace and defense applications anymore that require high reliability and lower weight. Due to their ability to be miniaturized, rigid flex PCBs are making their way into more mainstream applications such as high-end consumer electronics and advanced medical devices. But that comes at a higher cost.

Our new whitepaper explains it all:

Whitepaper Download: Why Rigid Flex is More Costly Than Traditional PCBs

In this free whitepaper, we share:

- Why additional layers mean additional cost and a more complex construction

- How rigid flex requires more accurate dimensioning, additional surface finishes

- Why mistakes can be costly when a project isn’t specifically designed for rigid flex

- How engineers can keep costs under control

- Why sometimes rigid flex is the inevitable option

LET'S TALK E2E

Ready to take the next step and explore powerful design innovation?

Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance