FLEX HEATER FAQ

These are the top questions asked about Heaters. Click on the question below to reveal the answer.

Polyimide Heaters

All-Polyimide Heaters

Silicone Rubber Heaters

Silicone Rubber Wire-Wound

Mica Heaters

Thermal-Clear Transparent Heaters

Because the mass of a Thermofoil heater is very small, they are generally not suitable for heating in the air. Thermofoil heaters operate best when mounted to an object that can be heated by conduction rather than convection or radiation.

The size of the non-heated lead attachment area varies based on the leadwire size, insulation material, lead exit location and heater dimensions. For a polyimide (e.g. Kapton™) insulated heater these range from 0.25 x 0.30” (6.35 x 7.62mm) to 0.5 x 0.8” (12.7 x 20.32mm) for sizes AWG 30 to AWG20. Describe your space limitations when specifying a custom design. Lead can be attached to a non-heated tab outside the body of the heater.

Minco standard heaters with polyimide, silicone rubber or mica insulation are tested to verify 1000 VAC minimum dielectric breakdown voltage. We can provide custom models with thicker insulation to increase the dielectric rating, but this will reduce the maximum power and temperature ratings for the heater. Another consideration is the amount of dielectric leakage current at operating voltage. Because an etched element covers 50% or more of the heater surface area, it can act as a capacitor when AC power is applied. The result is a leakage due to the capacitive effect. This is not a failure of the insulation but it may exceed the very low limits required for some medical and other applications. Minco can use special design techniques to minimize this leakage if your application requires meeting tight limits.

All-Polyimide, Silicone Rubber and Mica heaters offered on Minco.com/store utilize heater elements that are low TCR. So the heater resistances stay constant even as temperature changes. A typical TCR value for these heaters is 0.0005Ω/ Ω/°C. If required, Minco does have the ability to etch on high TCR foils such as nickel or nickel-iron. Please Contact Us if you require high-TCR foils (e.g. 0.00519Ω/ Ω/°C).

All Thermal Clear transparent heaters in Minco.com/store use high TCR wire. The heaters are calibrated at room temperature. The heater resistance will change as temperature changes in a positive coefficient manner.

Generally the answer is no. The materials used in polyimide insulated Thermofoil heaters are waterproof, but edges are not sufficiently sealed for immersion. Custom designs (including all PTFE heaters) can include increased border areas and sealed leadwire connections that make these heaters immersible in water. Silicone rubber insulated heaters require RTV cement or similar materials along all exposed edges and leadwire attachment areas for immersion in water.

If your application requires contact with other liquids contact Contact Us with details and we can help design a solution.

No – Thermofoil heaters cannot be cut or trimmed. The element conductor covers the entire area to maximize the heat spreading effect of the etched-foil design. Cutting into this would create an electrically open circuit and expose the electrically live element.

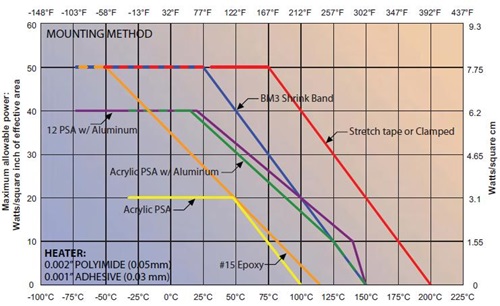

Foil helps to spread heat between heater strands, improves adhesion of PS, and makes polyimide less springy for better conformance to curves. It increases the temperature and watt density ratings of polyimide heaters with PSA. For silicone rubber heaters, foil with acrylic PSA is less expensive than #12 PSA applied directly to the rubber.