When precision and reliability matter most, engineers turn to Minco. Our new rotating bolt temperature sensor redefines bolt-on RTD design by solving one of the most common pain points in sensor installation – leadwire strain and twisting.

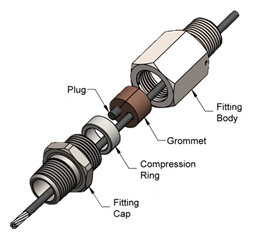

Traditional bolt-on sensors can be difficult to install in confined or dynamic spaces, where rotating or repositioning the sensor can twist the leadwire, creating stress points that eventually lead to failure.

Minco’s Rotating Bolt Temperature Sensor eliminates that risk. Its unique independent cable rotation design allows the leadwire assembly to swivel freely within the stainless-steel housing. That means easier installation, less mechanical stress, and greater long-term reliability — even in tight or vibration-prone environments.

Engineered for the Toughest Applications

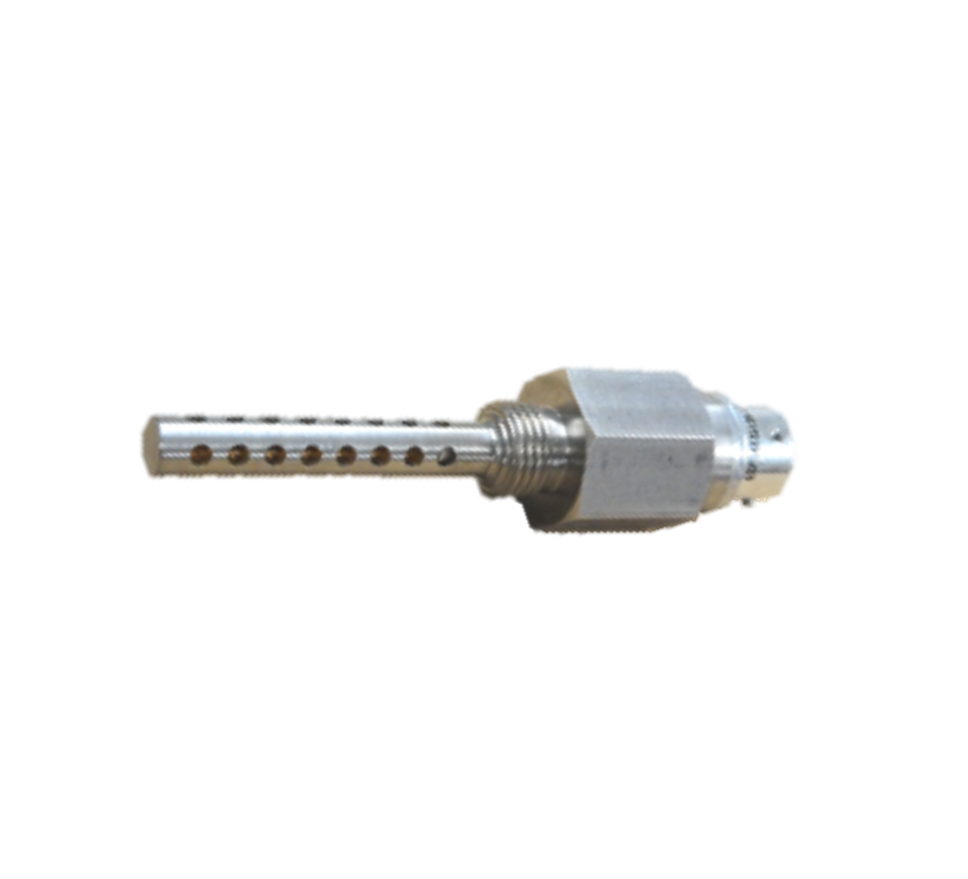

Built from rugged stainless steel and designed for high-vibration environments, this sensor is ideal for engines, compressors, generators, and industrial machinery — anywhere accurate surface temperature monitoring is essential.

The sensor’s vibration-resistant construction and high insulation resistance (1,000 MΩ at 500 VDC) ensure stable, long-lasting performance. For applications in aerospace, power generation, and medical equipment, reliability is non-negotiable — and Minco’s Rotating Bolt Sensor delivers.

Available with Hazardous Certifications

These certifications allow global OEMs to standardize across multiple markets and applications without redesigning or recertifying sensor configurations: IECEx (Worldwide), SIL2 (Worldwide), ATEX (Europe), CSA (USA/Canada), KCs (Korea), PESO (India), CCC (China).

Designed to Fit Your System

Minco understands that no two systems are alike. That’s why the Rotating Bolt Temperature Sensor is available in multiple configurations to fit your exact needs:

- Thread options: 1/4-20 or M6 x 1

- Temperature range: –50°C to +260°C (depending on configuration)

- Sensing elements: Nickel or Platinum RTDs with multiple tolerance classes

- Leadwire options: PTFE, PTFE with stainless-steel braid and/or FEP jacket covering or stainless-steel braid with FEP jacket and elastomer fill.

- Custom lead lengths and termination methods available

Optional features like stainless-steel feedthroughs prevent oil seepage when used with pressure seal fittings, making the sensor a smart choice for sealed or fluid-exposed assemblies.

Key Advantages:

- Independent cable rotation — prevents wire twisting and simplifies installation

- Flexible configuration — choose element type, lead style, and length

- Rugged design — stainless-steel case for demanding applications

- High insulation resistance — 1,000 MΩ at 500 VDC minimum

- Certified for hazardous areas — multiple international standards available

- Customizable dimensions and terminations — tailored to your application

Built on Minco’s Legacy of Reliability

For over 65 years, Minco has set the standard for temperature sensing technology — from mission-critical aerospace systems to industrial automation and medical equipment. The Rotating Bolt Temperature Sensor continues that legacy with innovation that simplifies integration, reduces maintenance, and enhances system reliability. For more information see all product specifications in the Rotating Bolt Temperature Sensor

Datasheet or contact Minco at custserv@minco.com.

LET'S TALK E2E

Ready to take the next step and explore powerful design innovation?

Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance