In the highly regulated medical device industry, performance, reliability, and patient safety depend on more than high-quality individual components. True innovation comes from integrating critical technologies into a single, optimized system.

As medical analyzers evolve from large, floor-standing systems to compact countertop designs, intentional integration has become essential. By combining temperature sensors, flexible heaters, and flex PCBs into coordinated assemblies, manufacturers can reduce device size, improve thermal response, and increase processing speed—without sacrificing accuracy or reliability.

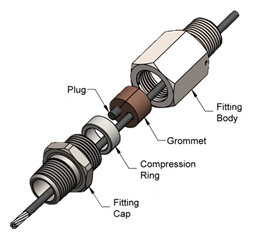

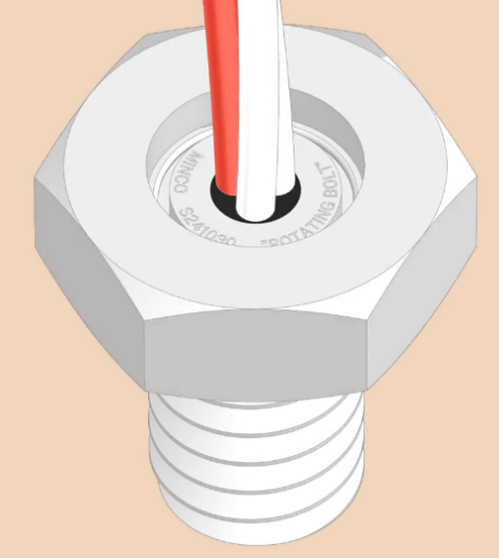

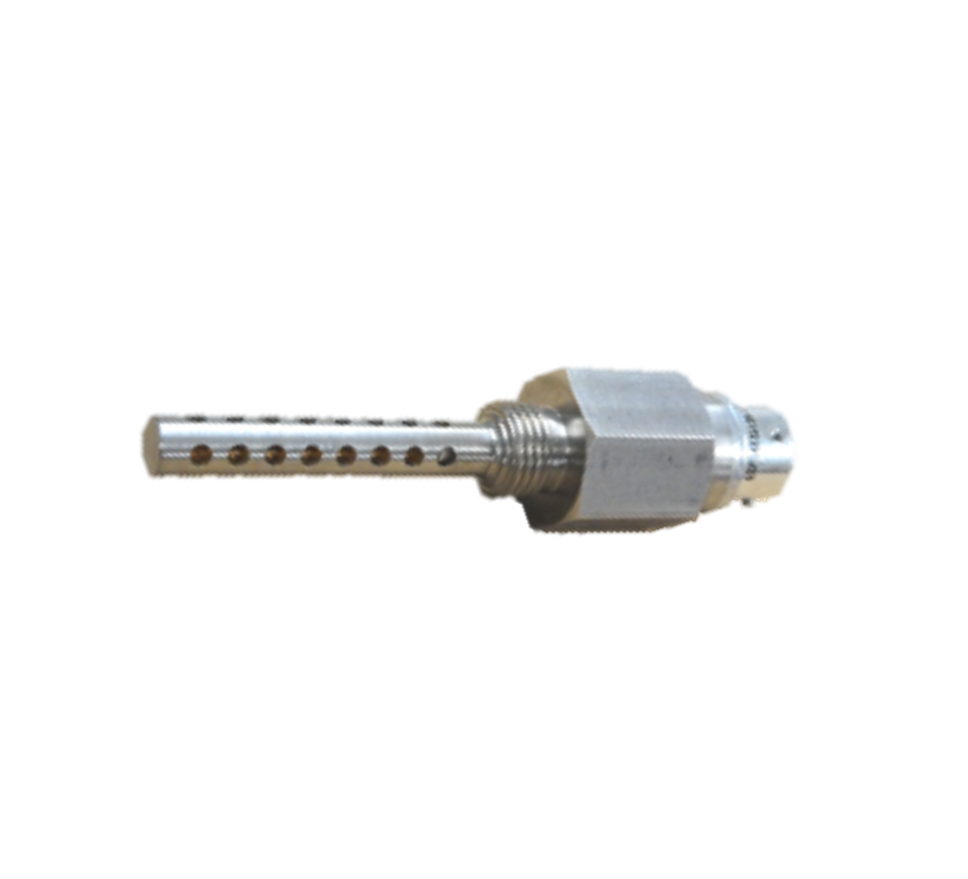

Minco’s integrated thermal solutions apply heat precisely where it’s needed using flexible heater technologies such as Thermofoil™ and SmartHeat SLT™, paired with closely coupled temperature sensors for fast, accurate feedback. Advanced sensor designs, including rotating bolt temperature sensors, further simplify installation and improve long-term reliability in space-constrained medical devices.

Flex PCBs complete the system by replacing bulky wiring and rigid boards, enabling three-dimensional routing, improved signal integrity, and simpler assembly. Together, these integrated technologies allow designers to achieve smaller footprints and more efficient medical systems.

By serving as both component supplier and integration partner, Minco helps medical device manufacturers reduce complexity, streamline supply chains, and accelerate time to market.

Read the full document: “Innovating Medical Devices Through Integrated Component Design”.

LET'S TALK E2E

Ready to take the next step and explore powerful design innovation?

Minco engineers are ready. Our thermal, flex circuit and sensing experts can help your team find a better way — minimizing costs, while improving overall system performance