MINCO

INSTRUMENTS

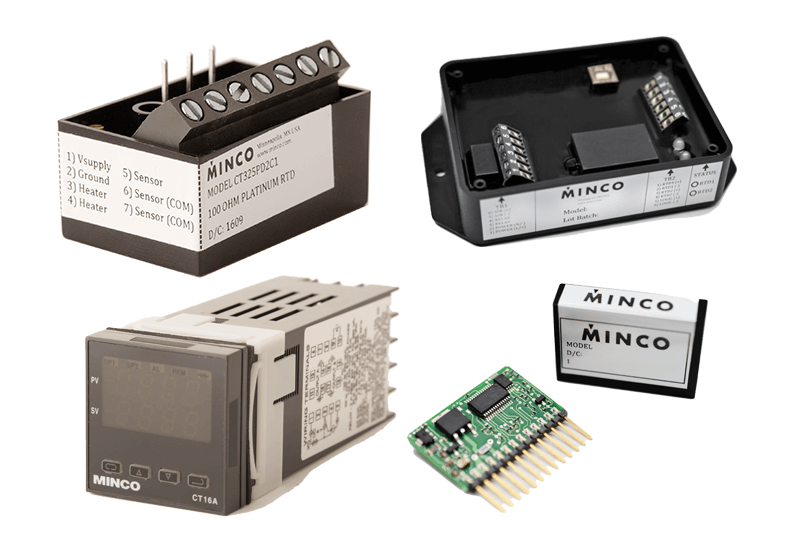

Controllers

Minco specializes in standard and fully integrated custom control applications that leverage a variety of control methods—including on-off, proportional, PID and sensorless functionality. Versatile packaging options ensure Minco controllers can meet a range of size, shape and mounting requirements.

Explore our full portfolio of Controllers:

- PCB Mount Controllers

- PCB Mount PID Controllers

- Compact 1/16th DIN Controllers

- Miniature DC Controllers

- Multi-Function Prototype Controllers

- HeaterStats

Need help building the right part?

Build a part number according to your specifications.

Interested in a standard part?

We’re here to help you find exactly what you need.